Describe the Process of Lager Beer Production Using Sorghum

In this study sorghum and sorghum malt were used as ingredients. Lager beer is produced from 100 sorghum using exogenous enzymes.

Try A Hazel Grove Beer At A Fish Fry Visit Full Pint S New Taproom And Other Beer News

The mashingofsorghummaltaloneorin combinationwith sorghumgrit at varyingproportions withand without the addition of external enzymes have also received adequateattention.

. Billed as The Original Gluten-Free Sorghum Malt Beer Bards American Pale Ale-style beers use 100-percent malted sorghum in entirely gluten-free facilities. Forty-nine sorghum cultivars of various origins were evaluated for Aspergillus contamination mycotoxins α- and β-amylases and β-glucanases after malting. The germinating process is then interrupted at the optimal stage by the drying kilning.

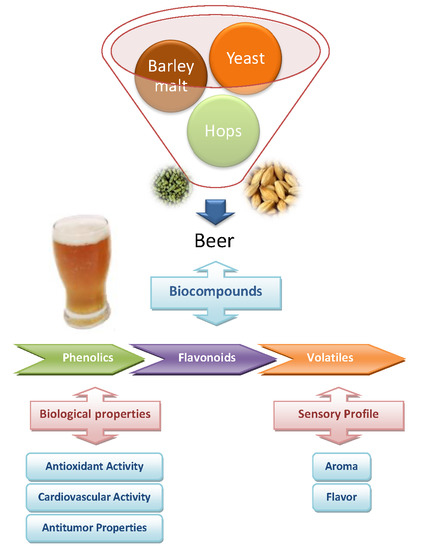

In the mash it is hydrated its enzymes break down starches to sugars and the sugar-containing wort is boiled cooled and fermented with brewers yeast. Stages of beer production with sorghum viz malting kilning mashing and fermentation2-2170-9293. These stages and procedure starts with the cleaning operations of the sorghum used which is the main raw material for brewing and then to other stages such as mashing filtration centrifugation sparging lagering bottling pasteurization packaginglabeling and final delivery to the consumer.

The introduction of beer from 20 malt and 80 raw sorghum is responsible external enzyme to 100 gelatinised sorghum malt for high resistance to non-biological haze formation but during mashing produces lager beer comparable to low head retention. These processes have to be monitored more frequently by regulating the temperature pH moisture content viscosity time alcohol content CO 2 and inputs water yeast and malt at different levels of production. In Africa this beer is brewed using sorghum grains.

The first step in the production of beer is malting. Optimizing conditions for malting mashing and fermentation are therefore necessary for the production of acceptable sorghum lager beer. Yeast converts the sugary wort into beer by producing alcohol a wide range of flavors and carbon dioxide used later in the process to give the beer its sparkle.

The major difficulties encountered when producing a lager beer with sorghum malt were investigated. Wort is cooled down and microorganism yeast is added at a rate of 715106ml. In combination with Lactobacillus plantarum as starter cultures was also used successfully for the production of pito sorghum beer having testa and aroma similar to that of.

To lager the beer slowly drop the temperature 24 F per day until the beer reaches 31 F 1 C or as close to that temperature as possible. The temperature of water depends on the type of malt and grain. Lactic acid fermentation can be initiated by adding some malted or raw sorghum grains to the mixture.

After fermentation the young green beer needs to be matured in order to allow both a full development of flavors and a smooth finish. Lager beer is produced from 100 sorghum using exogenous enzymes. Firstly the fresh barley gets soaked in water and put in the so-called germinating boxes to germinate.

Letting the mixture ferment naturally is another way to sour it. In brewing too malted sorghum behaves very similarly to malted barley. The 65C standard mashing procedure limited extract recovery from sorghum malt due to inadequate gelatinization of sorghum starch.

Beer is produced from barley grains. Then excess water is drained away and the barley are incubated for 4-5 days to allow germination. Barley kernels or the grains that are being used for beer brewing are crushed for the purpose.

Up to 10 cash back Soluble and insoluble amylases in grain sorghum contribute towards the hydrolysis of grain constituents during mashing. Bards continues to have a loyal following and will be ramping up production of their trendsetting sorghum beer in 2018. The process starts with the brewer soaking barley kernels in hot water.

Steps involved in beer production are. This review aims to update research results on lager beer brewing with sorghum. A good adjunct should have low saccharification time and should have the highest percent extraction of grain.

The average extract yield was 827 n 55 with a maximum of 893 and a minimum of 743 Fig. At the end of fermentation the beer is known as green beer which is harsh bitter and contains alcohol as well as aldehydes. Sorghum Malt Wort A three-step mashing procedure was used to investigate sorghum malt wort characteristics see Experimental.

The use of 11 cerevisiaeS. After this the foamy beverage is absolutely transparent and ready for bottling. These values contrast with previously reported data which were demonstrably low 573.

Equipment for beer maturation. This phase is referred to as steeping. There are procedures and stages in the industrial brewing of lager beer.

Agreat deal of analyses have been. Unmalted sorghum can also be used as a starch adjunct in brewing. During the final stage of production beer is poured into containers of different.

In this phase the enzymes amylase are formed which are needed for the starch separation. The fermentation process takes place in 3-4 days. Sorghum showed highest amylase activities at 96.

After maturation the beer passes another filtering with two different filters designed to remove large and small particles. However the use of sorghum Sorghum vulgare for beer elaboration in an industrial plant was launched only three years ago in the US. The time of soaking is about 40 hours.

At this point the beer is fully or nearly fully fermented and the true lagering period begins. For many years commercial breweries have experimented making beer from grains other than barley among which we can find wheat corn and rice. The brewing process of sorghum beer is in three forms-physical biological and chemical processes.

The out-of-steep moisture of sorghum is lower than expected 3336 but is adequate for enzymic modification of endosperm substrates of sorghum producing sufficient amylolytic enzymes for brewing lager-type beers. Souring can also be done using yogurt or cultures used as sourdough starters. Barley grains are first cleaned and then soaked in water for about 2 days.

Allow the beer to lager at 31 F 1 C for 412 weeks. Generally the longer the better. The lager beer from sorghum malt and adjunct showed superiority in.

The lager beer from sorghum malt and adjunct showed superiority in composition such as increased free alpha amino nitrogen and color units in sorghum malt and adjunct beer. The use of starter cultures also reduces the organoleptic variations and the microbiological instability of African fermented food. More than 60 sorghum malt samples were used in a laboratory-scale brewery and the major.

During this process it undergoes both alcoholic and lactic acid fermentation.

How Craft Breweries Are Changing The Beer Industry In South Africa Cnn Business

The Tea Book Dk Amazon Co Uk Dk 9780241182284 Books Plants Tea Fine Tea

What S The Best Gluten Free Beer

Beer Brewing From Home The Experts Tell Us How To Do It Properly

13 Of Great Tasting Gluten Free Beers Omission Green S Redbridge More Shape

:max_bytes(150000):strip_icc()/cream-ale_main_720x720-0d518d1066a44d458d0f2872f2d4cb9e.jpg)

Cream Ale What It Is And 5 To Try

5 Beers You D Never Guess Are Gluten Free Food Wine

Sorghum And More Exotic Grains Used In Gluten Free Beer American Sorghum

Malts Yeasts Hops And Grains Wine And Beer Kits Means Cork And Cap 814 227 2404

Estrella Damm Daura The Star Of Gluten Free Beers Gluten Free Beer Gluten Free Alcohol Gluten Free Cocktails

Applied Sciences Free Full Text Maize And Sorghum As Raw Materials For Brewing A Review Html

Enzymes Used In Brewing Process Infinita Biotech

Tap List Beer Hall Lakefront Brewery

New Grist Year Round Beer Lakefront Brewerynew Grist Year Round Beer Lakefront Brewery

3 Floyds Brewing Rotating Beer Series Price Reviews Drizly

Molecules Free Full Text Beer Molecules And Its Sensory And Biological Properties A Review Html

Comments

Post a Comment